Mobile cone crushers are widely used in the mining and aggregate industries for crushing various materials into smaller sizes. Proper maintenance and care are essential to ensure the efficient and reliable operation of these crushers.

Maintenance Schedule

Developing a regular maintenance schedule is crucial for mobile cone crushers. This schedule should include routine inspections, lubrication, and component replacements as needed.

Inspections

Regular inspections of the crusher components such as the crushing chamber, conveyor belts, and hydraulic systems are necessary to identify any signs of wear or damage.

Lubrication

Proper lubrication of all moving parts is essential to prevent friction and reduce wear. Grease should be applied according to the manufacturer’s recommendations.

Component Replacements

Worn or damaged components should be replaced promptly to avoid further damage to the crusher and ensure optimal performance.

Cleaning

Regular cleaning of the mobile cone crusher is essential to remove dirt, debris, and buildup that can affect its performance. Use appropriate cleaning agents and follow safety guidelines when cleaning the crusher.

Storage

When the mobile cone crusher is not in use, it should be stored in a dry and sheltered location to protect it from the elements and minimize the risk of corrosion.

After-Sales Service and Wear-Resistant Spare Parts Supply

After-Sales Service

Choosing a reputable manufacturer or supplier for your mobile cone crusher ensures access to reliable after-sales service. This includes technical support, troubleshooting assistance, and maintenance training for your operators.

Wear-Resistant Spare Parts Supply

Regular wear and tear are inevitable in crushers, but having access to high-quality wear-resistant spare parts can minimize downtime and extend the lifespan of your equipment. Ensure your supplier offers a reliable supply of spare parts tailored to your crusher model. You can check more from our AIMIX official website.

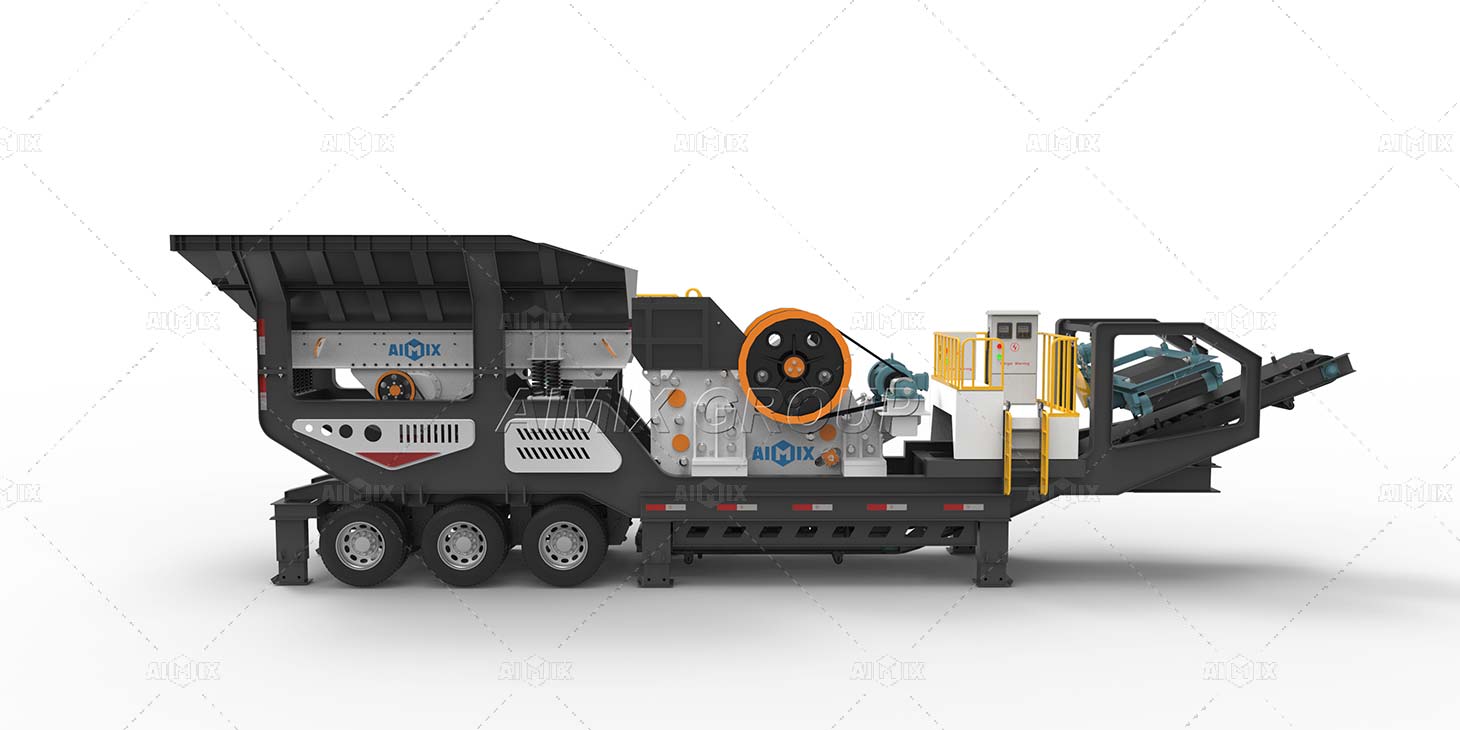

Comparisons Among Mobile Jaw Crusher, Mobile Impact Crusher, and Mobile Screening Plant

Raw Materials

Mobile jaw crushers are ideal for processing various types of hard and abrasive materials, while mobile impact crushers are suitable for softer materials with lower abrasiveness. Mobile screening plants are versatile and can handle a wide range of materials.

Output

Mobile jaw crushers typically have higher throughput rates compared to mobile impact crushers and screening plants due to their larger feed openings and higher crushing capacities.

Shape of Finished Products

The shape of finished products produced by mobile jaw crushers and impact crushers can vary depending on the crushing mechanism and the specific requirements of the application. Mobile screening plants produce multiple sizes of finished products based on the screening process.

Characteristics

Mobile jaw crushers offer excellent mobility and flexibility for onsite crushing operations. Mobile impact crushers provide high crushing efficiency and versatility for various applications. Mobile screening plants are efficient for separating different sizes of materials and can be used in conjunction with other crushing station.

Cost and Applications

The cost of mobile jaw crushers, impact crushers, and screening plants can vary depending on factors such as capacity, features, and brand. Each type of equipment has its unique applications in industries such as mining, construction, and recycling.